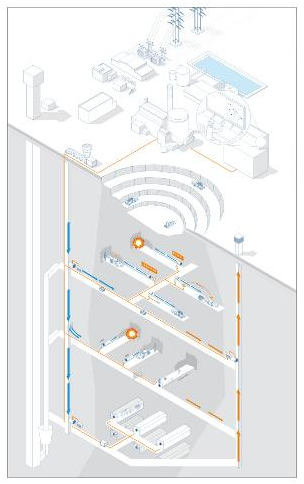

Power and automation technology group ABB has unveiled its SmartVentilation system, which supplies fresh air and vents toxic gases from subterranean mines.

As the new system has the ability to work ‘on-demand’ it is expected to reduce a mine operator’s electricity costs by up to 50%.

SmartVentilation is divided into SmartBasic, SmartMid and SmartPerfect implementation levels, each providing different degrees of control over the operation of the mine’s intake as well as exhaust fans.

Mine operators can install one implantation level and then upgrade it at their own pace.

Available in modular form, the fans and their drives are controlled with ABB’s System 800xA, an industrial automation platform.

The SmartVentilation system can provide a real-time analysis and control system to ensure working conditions are safe and energy efficient, the company claimed.

Using the technology, operators, engineers and mine managers can easily supervise and control the ventilation system, either from a central location or using mobile devices.

ABB global product manager for integrated mine automation Patrik Westerlund said: “The SmartVentilation is a state-of-the-art control solution for mine ventilation that was built to be easy-to-use and maintain during the lifetime of the mine.”

ABB’s worldwide service organisation is present locally making sure that the customers’ ventilation systems run effectively and efficiently.